Main specification

As a standard, our power supplies are protected against arc with the arc detection feature. This feature can be improved with the arc management option, allowing different behaviours when consecutive arcs are detected.

This option allows the user to set the behaviour of the power supply when it detects consecutive arcs at its output.

As a standard, our power supplies are protected against arc with the arc detection feature. This feature can be improved with the arc management option, allowing different behaviours when consecutive arcs are detected.

An arc is an unexpected discharge, directly to the ground, of the load connected to the generator’s HV output. Such discharge could result, for example, from an isolation failure or from the failure of a component.

A generator exposed to a series of consecutive arcs at high frequency (>10Hz) can be permanently damaged. In order to prevent this risk, Technix generators include, as a standard, an arc detection feature.

In order to detect an arc event, the generator measures continuously the dV/dt on the HV output. To be qualified as an arc, the event shall result in a voltage drop of at least 30% of the set voltage, and in the same time the value of the dV/dt shall exceed 30%/ms.

Within 30µs to 60µs after an arc is detected, the generator’s HV output is inhibited during a stop time (called Tstop). After Tstop, the generator resumes its operation smoothly.

As a standard, Tstop is set to 100ms.

Other settings for Tstop are available on demand.

Also on demand, the generator can be configured to go into fault mode when an arc is detected. With this configuration, the user has to reset the fault in order to use the generator again. The procedure is explained inside the user manual.

As an option, Technix can supply an output signal on the remote interface which informs the user when an arc is detected.

The arc detection feature can be deactivated by the user, and the Tstop time can also be modified by the user. However, the warranty of the generator is not applicable if damages to the generator result from modifying the arc detection parameters.

In some cases, the user might need to be able to define a process regarding the behaviour of the generator when arcs are detected. For such requirement, Technix can offer the arc management option.

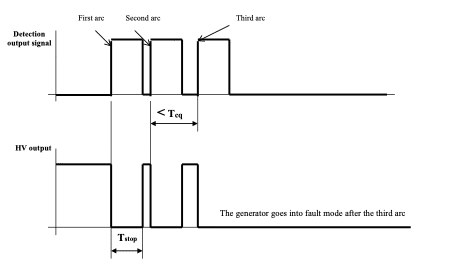

Each arc detected generates the arc detection process described above and increments a counter.

When the arc counting limit is reached, the generator goes into fault mode. The user has to reset the fault in order to use the generator again. The procedure is explained inside the user manual.

The arc counting limit is settable by the customer from 1 arc to 15 arcs, through 4 micro switches located on the rear panel of the generator.

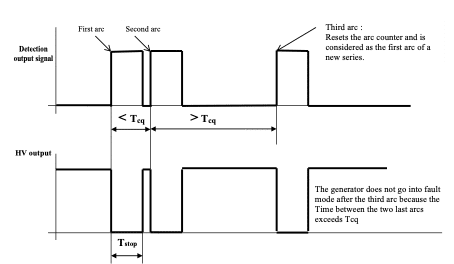

If the time between 2 consecutive arcs is too long, the second arc resets the arc counter.

The minimum time required between 2 consecutive arcs to reset the arc counter is called Tcq (Time for Counting Qualification.).

For example, for a Tcq set to 1.3 second:

- If an arc occurs within 1.3s after the previous arc, then the arc counter is incremented.

- The arc counter is reset if an arc occurs over 1.3s after the previous arc.

Tcq can be factory set between 1 to 3 seconds.

A fifth switch located on the rear panel of the generator allows the user to disable the Arc Management option.

However, the Arc Detection feature remains active even if the Arc Management option is disabled. The Arc Detection feature can be disabled separately.